IRMCO is not only known industry-wide for innovative and high-performance metal-stamping and tube-bending lubricants – but also for championing efficient and proper use of these lubricants. Our decades-long cooperation with manufacturers of lubricant mixing and application equipment helps us serve our customers’ needs at a truly unparalleled level. From tracking lubricant consumption – to mixing – to applying – IRMCO helps you optimize your stamping performance while eliminating unnecessary waste.

IRMCO will work with our customer’s existing proportioning and mixing equipment, but if more consistent, durable and cost-effective equipment and methods are available – we’d be happy and proud to recommend equipment that is most suitable for our customer’s unique needs and demands.

IRMCO’s oil-free, fully synthetic chemistries blend as true solutions in water – allowing for fine mists of lubricant to be delivered through spray nozzles. IRMCO also works with customers to optimize spray nozzle patterns, volumes and pressures to cut fluid consumption – maximizing efficiencies.

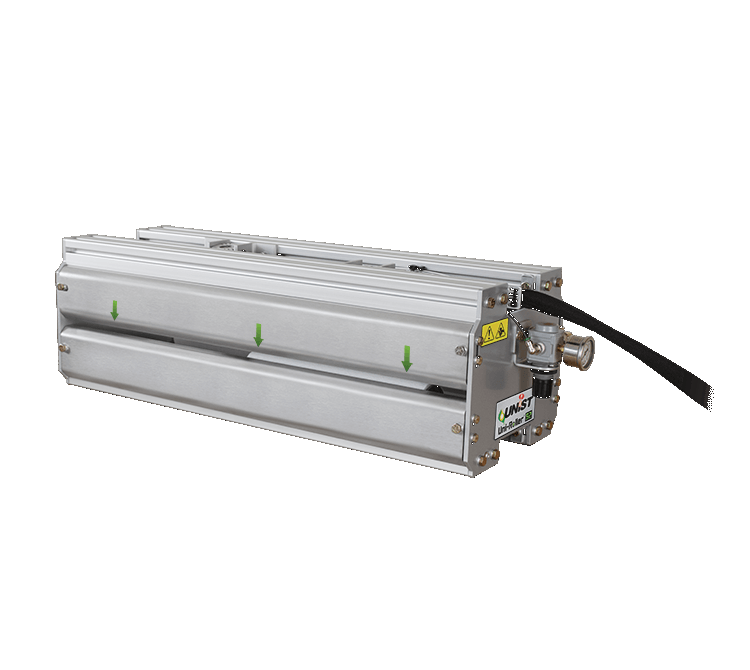

Generally best suited for coil-fed applications, conventional roller applicators have great compatibility with IRMCO FLUIDS®. Our products can be minimally applied through roller systems and we can also help integrate spray applicators to roller systems (through our industry relationships) for very demanding or specialized die designs.

The IRMCO iV PUMP SYSTEM was specifically designed for applying IRMCO GEL® & IRMCO EXTREME® lubricants through the mandrel in tube-bending processes. Just like an I.V. is used to deliver vital fluids to a patient – the IRMCO iV PUMP SYSTEM delivers just the right amount of vital lubrication to just the areas of the tube/tooling that require it.