Whether you’re at home, in a meeting or your child’s sporting event, you’ve got real time access to your stamping press downtime, lubricant consumption and concentration control.

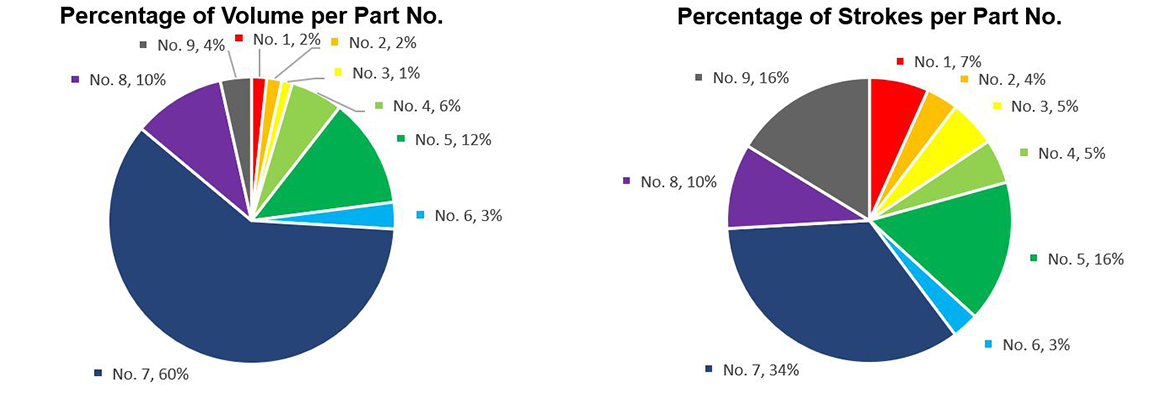

You can track the different rates of chemical consumption for individual parts, processes and compare this data to tool life to pinpoint the actual cost per part for each process in

your facility. What gives you this powerful insight into your stamping production? IRMCO iNSIGHT™ does.

- Track press down time and consistency of stamping lubricant consumption – getting alerts on production stops.

- Track and record the volume of lubricant solution actually consumed for any part, on any press, at any time.

- Monitor lubricant concentration control in real time – getting alerts when concentration or mixing changes.

- Track and record changes in process settings or variables from one shift to another in real time.

- Pinpoint the actual lubricant cost per part for your production items – allowing for the greatest degree of process optimization – improving your forecasting and contract bidding.

- Track your production processes remotely – providing uninterrupted data when COVID-19 quarantining effects safety/personnelavailability.

U.S. Patent No. 11,199,294