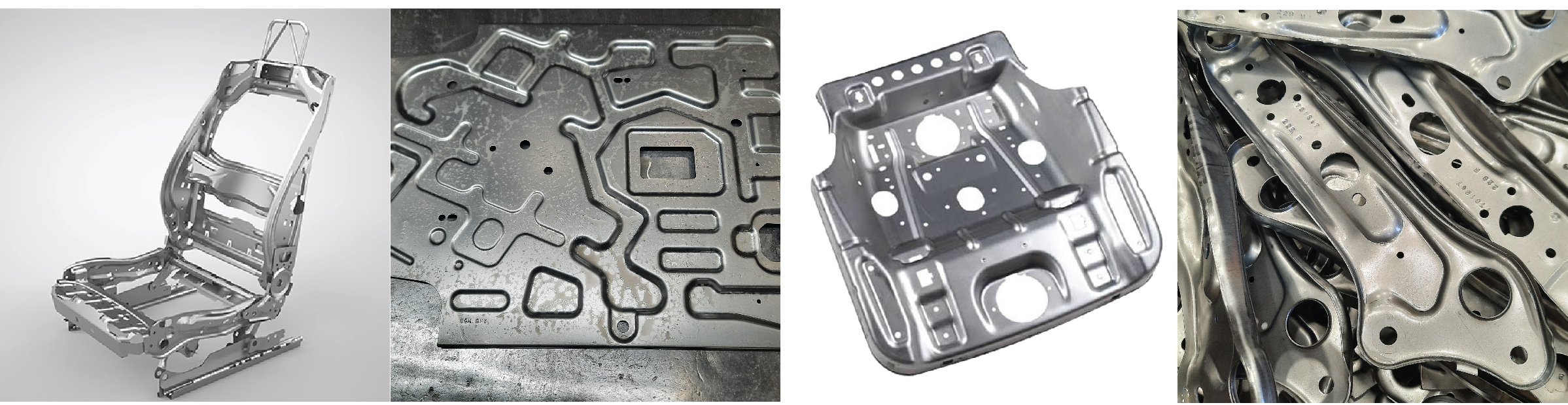

Automotive seating systems must be designed not only for driver and passenger comfort – but most critically for safety. As such, the materials and designs employed over the years have evolved into lighter weight and stronger metals – helping contribute to increased fuel efficiency and safety for consumers.

These changes in metallurgy have increased the demand on stamping lubricants to provide maximum protection for tooling, while compensating for different tensile strengths and surface coatings of the metal substrates used. IRMCO has been an industry leader in providing oil-free, water-extendible stamping lubricants for the production of automotive seat components – yielding parts that weld more cleanly and can be removed using less energy in finishing systems.

If you’re looking to optimize your stamping processes and are struggling with process costs, part quality or increased labor associated with welding or finishing processes – grab a seat and give IRMCO a call. We’ve got you covered.