REFRACTIVE INDEX DEFINED

BRIX: HISTORY & APPLICATION

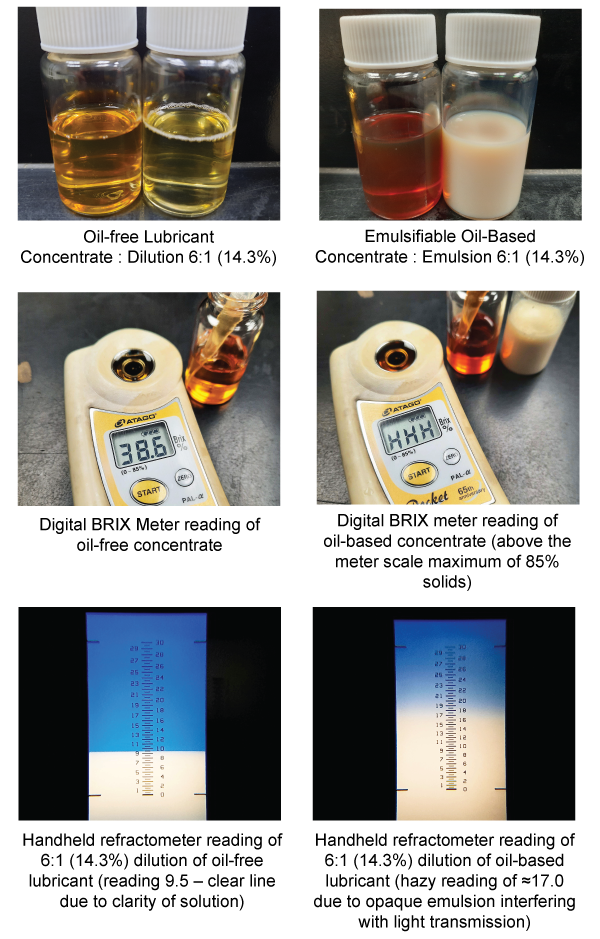

Today, the BRIX scale is commonly used in the food industry for measuring the approximate amount of sugars in fruits, vegetables, juices, wine, and soft drinks. It also finds use in the metalworking industry as a convenient way to check water-based lubricant concentration. As the BRIX measurement is based on the level of dissolved solids in an aqueous solution – it was adapted as a method for monitoring and controlling water-soluble stamping lubricant solutions. The use of portable, handheld refractometers and digital BRIX meters has allowed for more consistent process control in metal-stamping processes.

Measurement

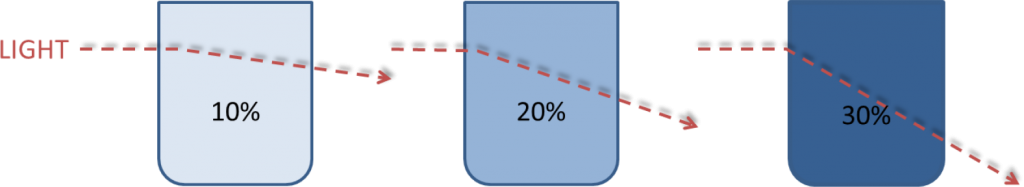

Because of the widespread availability of handheld refractometers, measuring the BRIX value of fluid is easy. However, not all solids bend light to the same degree. The actual concentration of a given fluid must be calibrated to relate to BRIX by the manufacturer. A conversion factor or Brix table should be provided for each product.

Interpretation

Not all solids are equal! In metalworking, BRIX is quite handy for monitoring dilutions, but it is less useful for comparing two different fluids. Depicted to the right are several fluids and their BRIX values. It is important to understand that although BRIX can be related to concentration, it says nothing about the nature of the solids. Put another way, a 64 BRIX could be a highly additized synthetic lubricant concentrate – or it could be maple syrup. A 32 BRIX could be a 1:1 mixture of that same lubricant – or it could be ketchup. One would be suitable for working metal – and the other would crash your die.