Stainless steel substrates:

- Comparatively hard, smooth surface profile compared to conventional steels.

- Work hardening properties of some alloys demand special lubricant properties.

- Used primarily for corrosion resistance properties.

- Historically required hard to clean/remove lubricants like chlorinated paraffins.

- Aluminized stainless steel substrates pose unique forming challenges – combining opposing physical, metallurgical characteristics of aluminum and stainless steels.

IRMCO SOLUTIONS FOR STAINLESS STEEL METAL-STAMPING:

- All IRMCO FLUIDS® products are free of chlorinated paraffins.

- Require less energy and less aggressive aqueous cleaning chemistry to remove.

- Typically improve weld quality due to cleaner surfaces.

- Better biodegradability than conventional, oil-based and chlorinated paraffin-containing lubricants.

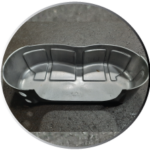

IRMCO FLUIDS® 080 SERIES: oil-free, fully synthetic, light – medium duty stamping of stainless steel automotive & appliance parts. Capable of complex geometries & deeper drawn parts. IRMCO FLUIDS® 536 SERIES: oil-free, fully synthetic heavy-duty stainless steel stamping lubricants for stamping complex geometries & deep drawn parts. Our unique chemistries include the following product lines: