Stamping lubrication is one is one of the most overlooked factors in managing plant productivity. Too often, the bulk of the attention in stamping processes falls on tooling design and the materials being stamped—but lubrication should be given closer scrutiny—especially beyond the mere price per gallon.

Granted; in the life cycle of part production, stamping lubricants (in and of themselves) typically account for a very low percentage of the actual cost of the part/s produced, but the ways in which they can affect other production areas is immense. Aside from the obvious impact on tooling and direct part scrap, stamping lubricants (and whether they are used appropriately) can have massive impact on housekeeping, welding, equipment lifespan, pretreatment processes and rework costs.

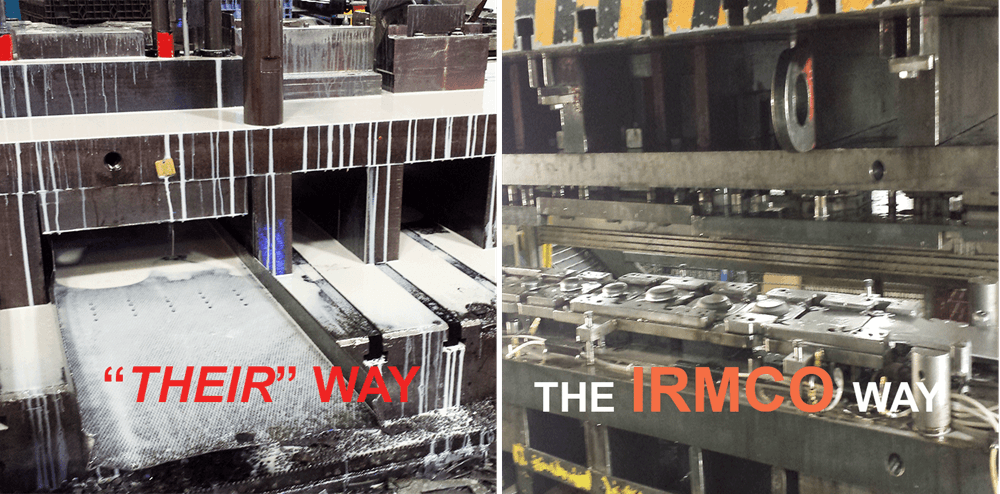

Lubrication strategies vary from plant to plant: some choose to use very low concentrations of lubricant, but must apply them in high volume to make them effective—flooding parts and tooling. Others will use lubricants at slightly higher concentrations, but apply them more sparingly and only where the parts or tooling really require the chemistry.

The following series of bulletins will attempt to shed more light on the hidden costs associated with the practice of using very low fluid concentrations at high volume and the potential benefits of employing higher/optimized lubricant concentration/s at much lower fluid volume.