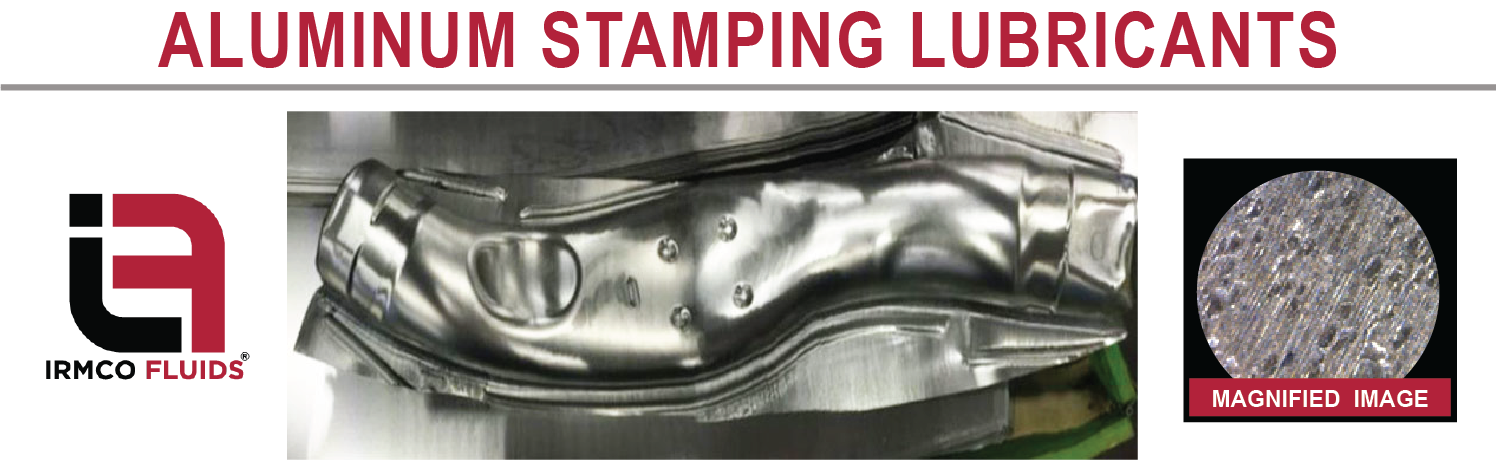

ALUMINUM SUBSTRATES:

- Gaining attention for automotive light-weighting purposes.

- “Softer” than conventional, HSLA & AHSS steels.

- Comparatively more “abrasive” surface oxides compared to steels.

- Challenging to form more complex geometries.

- Historically heavy reliance on chlorinated paraffin-based lubricants to form.

- Staining potential is greater than with steels – surface oxides harder to finish/paint.

IRMCO’s SOLUTIONS FOR ALUMINUM METAL-STAMPING:

- Mineral oil-free chemistries offer clean operation and inspection.

- Better biodegradability and safer environmental/regulatory profile.

- All water-based chemistries very compatible with lower temperature and lower pH cleaning.

- More compatible with aqueous cleaning and pretreatment systems.

IRMCO’s suitable aluminum stamping lubricants product lines include:

IRMCO FLUIDS® 080 SERIES: oil-free, fully synthetic, light – heavy- duty stamping of aluminum parts. The 080 SERIES is well suited for complex geometries and deep drawn parts. Parts include heat shields, instrument, door & body panels.

IRMCO FLUIDS® 090 SERIES: oil-free, fully synthetic, light – heavy- duty stamping of aluminum parts. The 080 SERIES is well suited for complex geometries and deep drawn parts. Parts include heat shields, instrument, door and body panels.