Do you have leaky spray nozzles? Are they dripping after they fire?

Years ago you invested thousands of dollars in spray equipment to control lubricant usage. Over time, hoses were damaged or cut. Maybe certain jobs required extra nozzles. Or some manifold ports stopped working and were never repaired. So somebody spliced hoses using “T” connectors.

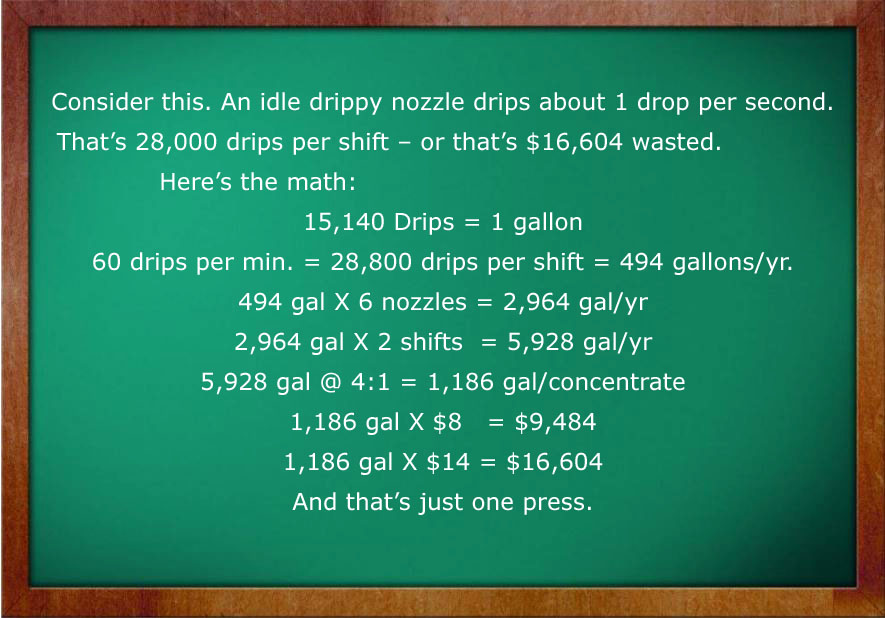

So what? Well, when you do that the “T” connection breaks the vacuum and lubricant drains and drips after the fact. After they fire, they empty. Like when you remove your finger from a drink straw the liquid just drains out. No big deal right?

Remove the T and the dripping stops. So does the waste. I’m betting your current stamping lubricant supplier hasn’t pointed this out to you.

Is that the kind of lubricant supplier you want? Is that the kind of lubricant supplier you deserve?

I don’t think so. Give IRMCO a call. Problem Solved.