Your customer demands clean tubes and assemblies—so will you need to add an intermediate cleaning step to remove bending lubricant residues—or will the surface be clean enough to meet specs without the use of solvent or aqueous cleaners and weld cleanly and properly?

Your customer demands clean tubes and assemblies—so will you need to add an intermediate cleaning step to remove bending lubricant residues—or will the surface be clean enough to meet specs without the use of solvent or aqueous cleaners and weld cleanly and properly?

Thicker, oil-based, fatty paste or grease-type lubricants will likely require some level of removal from tube surfaces if welding applications are to be undertaken. This is to provide clean welding surfaces to prevent porosity or failures and to ensure minimal residues are left behind for cosmetic reasons. Water-based or water extendable bending lubricants typically weld through with fewer issues— leaving behind more negligible residues—usually resulting in tubes that are “dry to touch” and cosmetically clean.

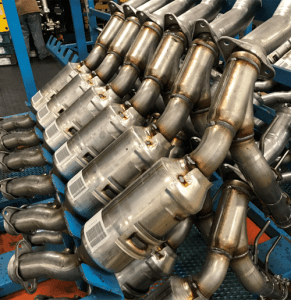

The greater the oil and/or fat content in your bending lubricant—the greater the chances for tube producing smoke at customers building heating elements and/or exhaust/emission systems when tubes are not cleaned. Lubricant chemistry will also impact how you are able to clean finished assemblies or individual parts. Some lubricants may require use of solvents to be adequately removed from tube surfaces –other lubricants may use aqueous cleaners but may require different levels of circulation or temperature to meet cleanliness specs.

Use of lubricants with pigments or particulates in their composition need to be especially evaluated for ease and completeness of removal as residual particulates may impact filters or valves in tubing systems used for fluid delivery or exhaust.